Blown Film Training and Troubleshooting

We at Plastics Touchpoint Group, Inc., are an innovative company in the flexible packaging industry, catering to the surging demand for expertise in blown film extrusion and film conversion operations. With a comprehensive focus on blown film extrusion, cast film extrusion, and film conversion, we have established ourselves as leaders in the global market.

Who makes the profit in your company? It is the people who actually produce the product your customers buy! Film extrusion and converting is a complex process with many pitfalls. The most cost effective way to increase profits is to train production staff properly. Plastics Touchpoint Group offers customized training in English and French. Programs are available at Introductory, Basic and Advanced levels.

Benefits:

This program is a proven, cost effective way to:

- Increase profits by improving production efficiency.

- Teach your production and quality control personnel what they need to know.

- Change your corporate culture from "good enough" to "best value for our customers".

- Improve your marketing tools by meeting ISO 9000 training requirements.

Each customized program can include the following modules:

1. Skills Assessment

Each participant is required to complete a multiple-choice Film Manufacturing Knowledge Survey which is customized for each manufacturing site. The test results are analysed to identify knowledge gaps. The information is used to customize the training program.

2. On-site Classroom Training

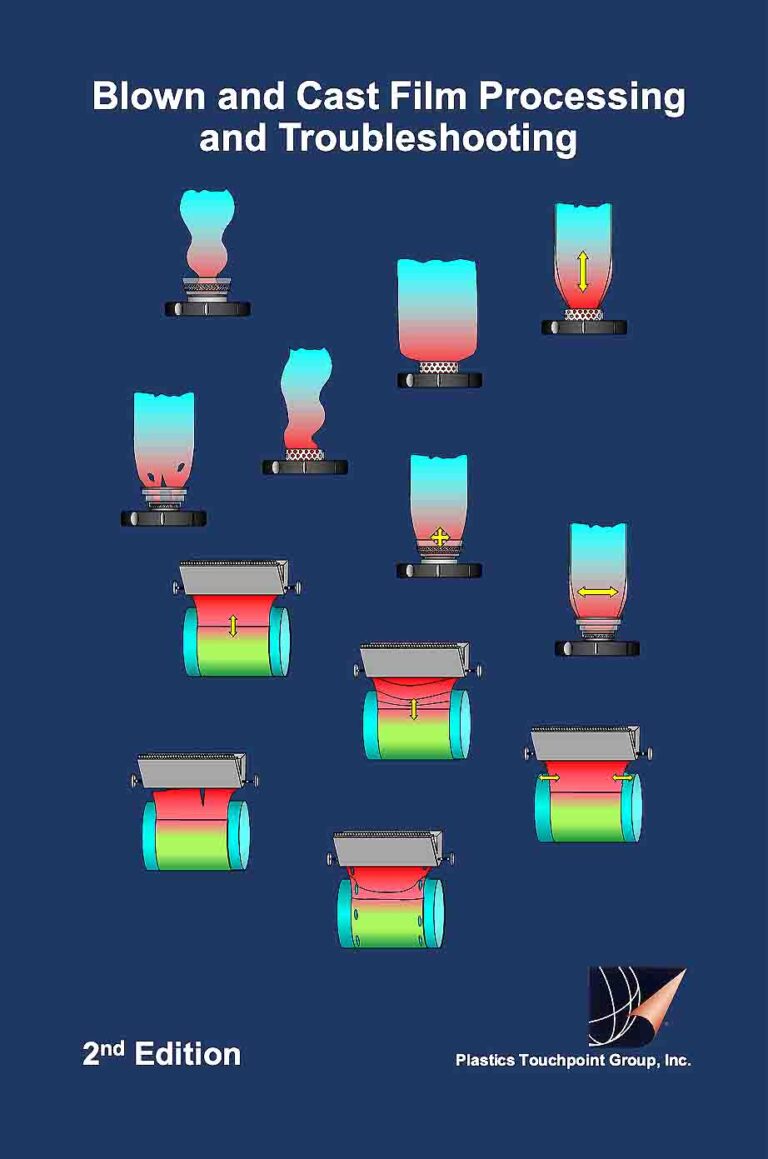

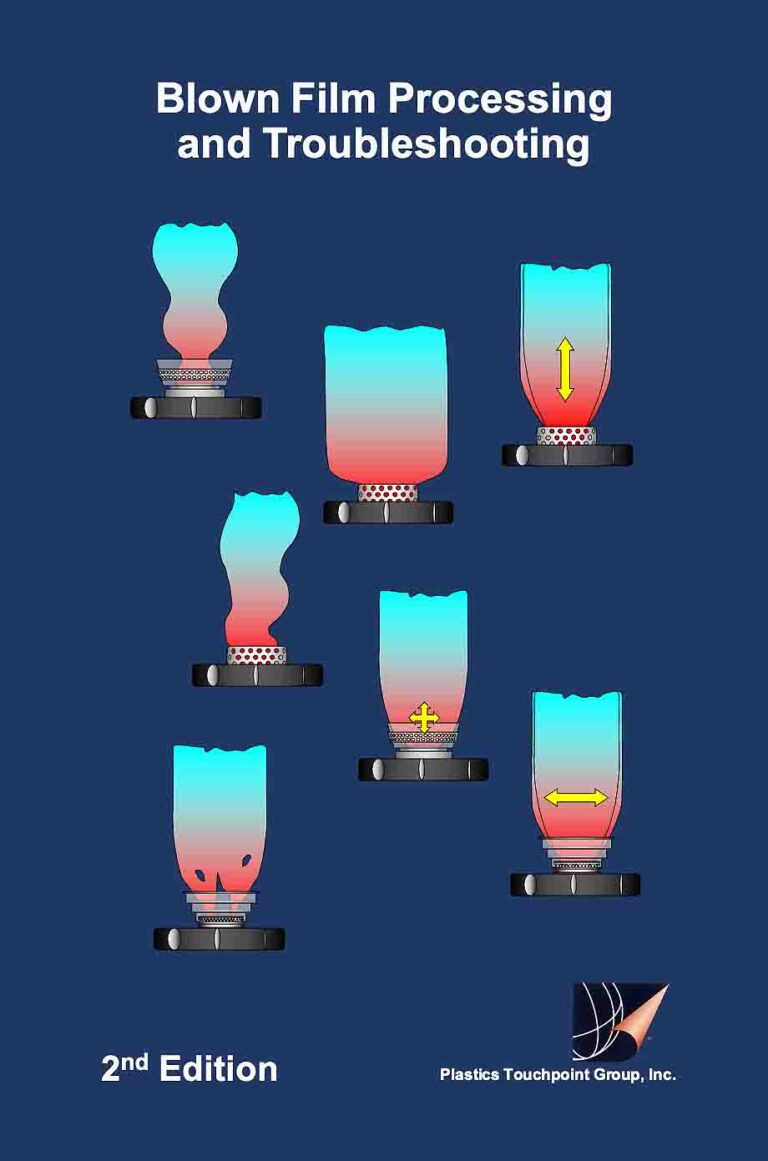

Classroom sessions cover the knowledge component of training. Topics include raw material characteristics and how all the components of film extrusion lines operate and affect each other. The program is structured to demonstrate troubleshoot strategies to fix common problems. Classroom sessions take 8 hours to complete. Options to split the training into two 4 hour sessions are available. Classroom sessions can be scheduled during a factory shutdown, or repeated several times while participants are not scheduled to work in the factory. Each participant receives a copy of our bestselling book: Blown Film Processing and Troubleshooting or Blown and Cast Film Processing and Troubleshooting as a reference tool to be used during all the training sessions.

3. Virtual Classroom Training (Optional)

Classroom sessions can be delivered remotely. Instruction is similar to in-person classroom training. Sessions are limited to 2 hours to accommodate your production schedules.

4. On-site Hands-on Training

Hands-on sessions cover the skills component of training. Hands-on training for each shift takes between 2 and 4 hours, and is conducted on the plant floor during normal operating hours. Participants have an opportunity to review key concepts discussed during the classroom sessions and demonstrate how to use them to troubleshoot problems detected during these training sessions. This portion of the training program focuses on adjustments to process equipment that will minimize scrap rates and maximize output rates. Training to use quality measurement procedures is included in this portion of the training program.

5. Training Assessment

Each participant completes the same multiple-choice test that was completed in the Skills Assessment module. Each participant receives a comprehensive analysis of their responses before and after training is completed, as well as the correct answers to each question.

6. Management Review and Follow-up

A detailed report is prepared that tabulates the skills improvement for all participants. A capabilities matrix developed by leading industry participants is suppled and review to assist in the development of future training programs.