Auxiliary Equipment

AFV Series Volumetric Additive Material Feeder

The AFV Series Volumetric Additive Material Feeder from Process Control is designed to inject colour concentrates or other additive-type materials directly into a material stream at the feed throat of an Extruder or moulding machine. The AFV Series is a simple, easy to operate feeder, offering unparalleled accuracy and cost savings to plastic processors.

Standard features include a horizontal solid-flight auger with a 0.19 KW (1/4 HP) variable speed AC gearmotor for precise metering of colorants or other additives into the virgin or virgin/regrind flow as it enters the machine throat. The digital controller can be configured for local manual speed control or can be synchronized to either follow an extruder rate or run in a remote run/stop mode for injection moulding processes. Other standard features include a sample port for feeder calibration, a clear view sight glass on either side, and a material drain port for easy clean-out and quick material changes. The hopper lid can be configured either for hand loading or with mounting provisions for a vacuum type loader.

The feeders are available in two different hopper sizes and various auger and gear motor ratios for rates of 1.1 to 1600 kg/hr (0.5 to 3,500 lb/hr). A central mounting adapter can accommodate up to (4) feeders for introducing various colours and/or additives into a single processing machine.

PF Series Powder Feeder

The PF Series Powder Feeder from Process Control offers operators unprecedented metering accuracy from ultra low rates up to 2700 kg/hr (6000 lb/hr). Incorporated into the brushed stainless steel design is a unique round-to-trough feeding area which provides more consistent mass flow for better metering accuracy. The feeder is designed with a steep wall, removable hopper which features a dust-tight band clamp for easy mounting of hopper extensions and quick disassembly for clean out. The bottom trough design is optimized to provide maximum material exposure to the auger. Separate DC-type drives for the agitator and metering auger allow appropriate agitation at all auger speeds. Metering augers are available in full pitch or 1/2 pitch configurations with helix diameters from 6 to 57 mm (1/4 to 2-1/4 inches).

The PF Series can be configured with controls for intermittent agitator operation, which is particularly useful when operating at very low rates. The variable speed agitator permits thorough mixing in all areas of the metering section. The unprecedented metering accuracy of the PF Series Powder Feeder is enhanced by a proprietary filtering method (pat. pend.) which allows very accurate and consistent gravimetric metering in the presence of ambient vibration and electrical noise. The feeder is available either as a stand-alone or configured as an element on a gravimetric. Options include: Blend Manager Software for integrating real-time trending, material management, and monitoring; Support stand with vertical outlet downspout and platform for loading equipment blender.

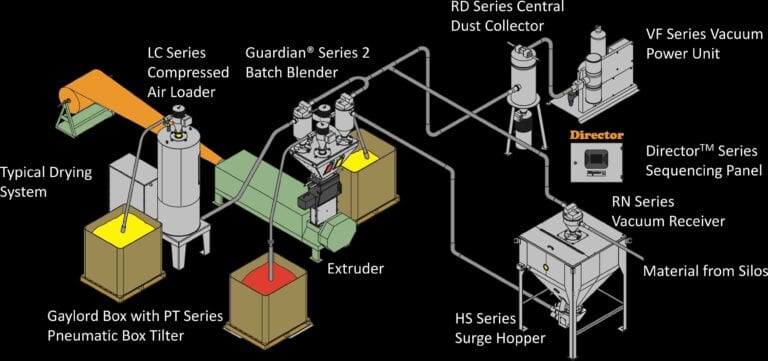

PCC Drying Solutions

Process Control Disiccant Wheel, Hot Air and Membrane dryers provide plastics manufacturers with a wide variety of solutions for specific drying or dehumidification requirements. Typical feature across various models include process stability, comparative energy efficiency and uniform process operations. Some models use significantly less energy, require lower maintenance and can save more on consumables.

PT Series Pneumatic Box Tilter

The PT Series floor pneumatic box tilter is and easy-to-use gaylord container tilter which offers fork lift, pallet jack or hand truck loading of bulk containers. Lifting action is adjusted with an air bag inflated to preferred pressure. The gaylord automatically tilts as it empties, moving material to the corner where the pick-up lance is placed. The compact design requires only 180 x 205 cm (71 x 80 in.) of floor space. Standard pillow pressure range is 275 to 690 kPa (40 to 100 psig).

Standard features include: 900 kg (2000 lb) capacity, adjustable pick-up lance holder, 45° maximum tilt angle, multiple angle loading configurations. Optional features include: vibrator for difficult flowing materials, castors, custom paint, pick-up lances.

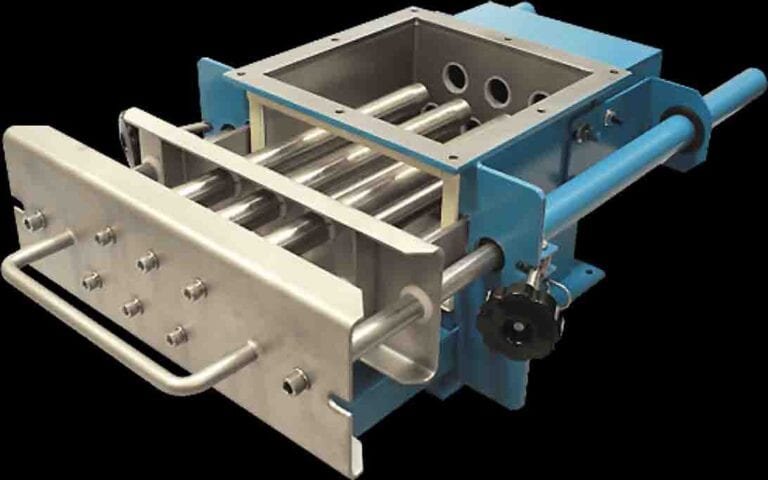

Tubing Hardware and Magnets

PCC supplies customized piping designs and installation. Heavy duty aluminum tubing is recommended for material flow lines. Drawer magnets are recommended to be installed at the entrance to all extruders. When space is limited, in-line magnets provide an alternative to drawer magnets.