Railcar Unloading System

Railcar Unloading System

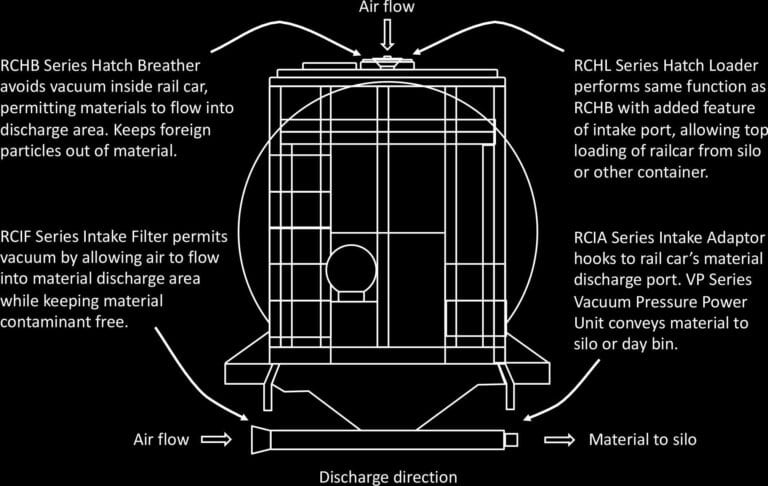

A typical railcar unloading system consists of railcar attachment hardware, conveying tubing, a vacuum pump, a transfer station, and a pressure pump. The system is designed to vacuum the material out of a railcar compartment into a transfer station which delivers the material to the pressure side of the system for conveying a silo or other in-plant destination.

VP Series Vacuum Pressure Power Unit

The VP Series Vacuum/Pressure power unit is typically used as part of a truck or railcar unloading system. It is designed to pull material to its transfer staation, where it passes through a rotary feeder to the pressure side of the system. The material is then blown to a storage container such as a silo or daybin. The VP series can be part of an integrated plant distribution system designed by Process Control to meet your specific needs. The T-frame TEFC motor size range is from 7.5 to 37 KW (10 to 50 HP). It includes a positive displacement blower, a discharge silencer, a vacuum relief valve and gauge, level control and a dual-stage intake filter.

VL Series Vacuum Power Unit

The VL Series vacuum power units are designed ensure a continuous supply of material to any number of plant sites, including silos, surge bins, processing machines and blenders using vacuum as part of a complete dual-blower railcar or truck unloading system. The VL series vacuum power unit pulls material from a source to a CH series transfer nation (availble separately). The material then drops through a rotary feeder to a blow through powered by a P series pressure power unit (see below). The material is then conveyed using pressure to one or many selected distribution points.

Standard features include T-frame TEFC motor in sizes from 7.5 to 30 KW (10 to 40 HP), positive displacement blower, dual stage intake filter, discharge silencer, vacuum relief valve and gauge, reinforced heat steel base plate, four-sided belt guard with removable access cover, electrical and controls in NEMA-12 enclosure, power 460V/3PH/60Hz and designed for outdoor service. Optional features include custom motors and electrical specifications, fused disconnect panel, proofing interlocks, level controls at storage or use points and custom paint colours.

CH Series Transfer Station

The CH series is used to transfer material from the vacuum part of te system to the pressure side. The VL pump creates the vacuum which pulls material from a rearilcare or bulk hopper truck into the cyclone mounted on top of the transfer station. The material drops through a rotary airlock feeder, into a blow through assembly. The P series ten applies the pressure to convene the material to its storage point, which is usually a silo or daybin. Standard features include a rotary feeder with shear eliminator and vent, a polyphase gear motor, a high efficiency cyclone, electro-mechanical level control rotary vane, and a four sided chain guard wth removal access cover reinforced heat steel base plate. Options include stainless tell construction, special part or epoxy coating and bathhouse type filter.

P Series Power Blower Unit

The P Series power units are designed ensure a continuous supply of material to any number of plant sites, including silos, surge bins, processing machines and blenders as part of the dual-blower system with VL series vacuum power units (see above). When combined with vacuum pumps, dual-blower vacuum / pressure systems can be configured to minimize power consumption.

Standard features include T-frame motor in sizes from 1.5 to 37.5 KW (2 to 50 HP), positive displacement blower, intake and pressure-side silencer, reinforced, heavy steel base plate, NEMA-12 electrical/control enclosure, cartridge type intake side air filter, adjustable pressure switch with diaphragm-piston transducer and four-sided belt guard with removable access cover. Optional features include custom motors and electrical specifications, custom paint colours, level controls at storage or use point and heat exchanger for cooling conveying air.