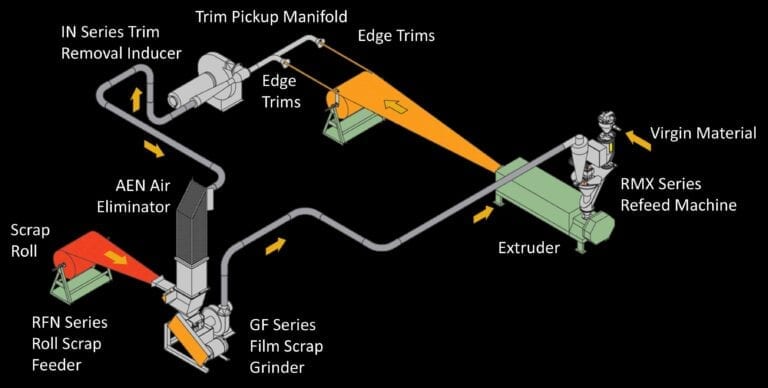

Trim Reprocessing System

RMX Series Refeed Machine

The RMX Series Refeed Machine is part of a complete ASR® Automatic Scrap Recycling System for recycling scrap generated on a film extrusion line. The RMX Series is specifically designed for use with Gravitrol® Gravimetric Extrusion Control Systems. The compact size also makes the RMX Series suitable for applications with headroom restrictions without sacrificing the performance that has made the ASR® Refeed Machine popular for film applications.

The unique, double-compartment RMX Series Refeed Machine operates with a variable-speed auger/bridge-breaker assembly to compact and meter ground scrap from the inner hopper to the throat of the production extruder. The outer compartment contains virgin material which is gravity-fed to the throat. The virgin material completely surrounds the ground scrap as it enters the extruder. The extruder screw receives a consistent column of compacted ground scrap surrounded by virgin material. This method provides consistent operation without extruder surging or starvation. With the standard extruder follower circuit, refeed machine will increase or decrease the scrap rate in proportion to the extruder speed. This holds scrap percentage constant without additional operator attention. The RMX Series Refeed Machine capacity range is from 0.57 to 3.4 m3/hr (20 to 120 ft3/hr), depending on the model selected.

GF Series Film Scrap Grinder

The GF Series grinders from Process Control Corporation are used as part of an asr® Automatic Scrap Recycling system for in-line recycling of production film scrap. GF Series grinders are designed to provide efficient, uniform grinding of film scrap. There are four cutting chamber sizes available along with motor sizes from 4 KW to 75 KW (5 to 100 HP) to accurately match the grinder to the required scrap rate. The GF Series grinders are available in configurations that accept edge and bleed trims, roll scrap, and loose scrap.

Standard carbide-coated knives are employed in the system, increasing the time between sharpening. The rotor knives approach the stationary bed knife, or knives, at a steep angle to ensure a clean scissors-cut. This technique is used for maximum bulk-density and flow of ground scrap. The open rotor design improves airflow for cooling , permitting the highest possible throughput. After the cutting chamber, material passes through a sizing screen that is chosen specifically for the application and material. The ground scrap is pulled through the grinder screen and carried through the process by the scrap conveying fan standard on each GF Series grinder.

RFN Series Roll Feeder for GF Series Film Scrap Grinder

Reintroduction of roll scrap is achieved with the attachment of an optional RN Series roll feeder. The roll feeder has knurled rolls that provide a strong pull on the film, without wrapping. They are available in several sizes with variable speed DC motors that run at 1 to 10 m/min (3 to 32 fpm). Inlet width range is from 110 to 350 mm (4.25 to 14 inches).The control panel for the grinders includes a motor starter for the grinder. When purchased as part of a complete ASR® system, the control panel includes controls for the inducers and roll feeder, as well.

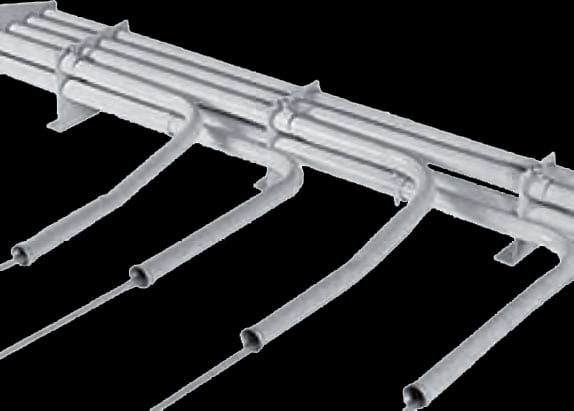

IN Series Trim Removal Inducer

Process Control’s IN Series Inducers are designed to pick up and convey edge and/or bleed trims generated in the production of plastic film or other thin-gauge products such as foam, tape, paper or foil. These continuous trims are picked up by suction, conveyed into the inducer’s venturi section and blown to a destination such as a Process Control film grinder or a waste container.

Process Control inducer manifolds are designed to insure that the air velocity at the pickup point is maintained so that trims do not wrap around the cutters. The IN Series inducers feature an adjustable venturi to allow you to tune the inducer for peak performance with your installation. IN Series inducers have a higher induced air to primary air ratio than conventional trim removal systems, providing excellent pickup and conveying performance.

IN Series inducers are designed to adapt easily to the installation requirements of your extrusion lines. The unit is shipped with its fan in a top- horizontal arrangement, but can be easily rotated in 90° increments to provide the required fan/venturi orientation. The fan may also be mounted remotely from the venturi using additional tubing. Motor size range is from 4 to 15 KW (5 to 20 HP).