Guardian® Series 2 Batch Gravimetric Blender

Guardian® Series 2 Batch Gravimetric Blender

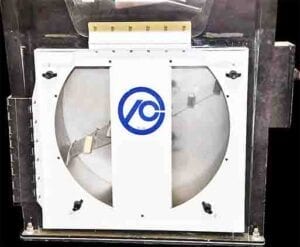

The Guardian® Series 2 gravimetric batch blender was developed for processors who want the simplicity of operation combined with the most accurate dispensing and superiour blend homogeneity at a low cost. For these customers, Process Control designed the Guardian® Series 2 blender with redesigned material hoppers to hold each of the ingredients in easy to clean material hoppers with no opportunity to hang up and contaminate blends when changing materials.

Each hopper has one 90° degree side an no transition sections for improved material flow. The hopper access doors have a secure latching system. Cartridge sale dispensing gauges with only 4 bolts to remove allow for easy of maintenance and rapid clean out. Optimized V-design metering gates provide improved accuracy and dispensing range. The control interface is via a 150 mm (6 inch) colour touch screen with ‘off-the-shelf” industrial controls. Remote communications is via the Ethernet port and supports standard industry protocols.

All Guardian® Series 2 gravimetric batch blenders come equipped with a fast acting V-gate valve for the material hoppers. Each of the materials is dispensed sequentially into a common weighing hopper in the desired proportions. The weighed materials are then released into a separate mixing chamber which provides the most consistent homogeneous blend of any batch type blender. Process Control engineers have developed a highly advanced dispensing and weighing system that accurately controls each ingredient of every batch to the desired amounts and is not averaged over multiple batches as is common in other batch blenders in the industry. At the blender’s most precise setting, each ingredient can be dispensed to an accuracy of ± 0.02%.

Batch Size

Throughput Capacity

Batch Size

Throughput Capacity

- 2 elements – 180 kg/hr (400 lb/hr)

- 3 elements – 180 kg/hr (400 lb/hr)

- 4 elements – 180 kg/hr (400 lb/hr)

- 5 elements – 155 kg/hr (340 lb/hr)

- 6 elements – 130 kg/hr (290 lb/hr)

- Maximum 6 elements

- 2 elements – 2175 kg/hr (4800 lb/hr)

- 3 elements – 1815 kg/hr (4000 lb/hr)

- 4 elements – 1360 kg/hr (3000 lb/hr)

- 5 elements – 1315 kg/hr (2900 lb/hr)

- 6 elements – 1270 kg/hr (2800 lb/hr)

- Maximum 12 elements

- 2 elements – 370 kg/hr (820 lb/hr)

- 3 elements – 370 kg/hr (820 lb/hr)

- 4 elements – 370 kg/hr (820 lb/hr)

- 5 elements – 315 kg/hr (700 lb/hr)

- 6 elements – 275 kg/hr (600 lb/hr)

- Maximum 6 elements

- 2 elements – 3175 kg/hr (7000 lb/hr)

- 3 elements – 2600 kg/hr (5750 lb/hr)

- 4 elements – 2315 kg/hr (5100 lb/hr)

- 5 elements – 1950 kg/hr (4300 lb/hr)

- 6 elements – 1770 kg/hr (3900 lb/hr)

- Maximum 12 elements

- 2 elements – 1000 kg/hr (2200 lb/hr)

- 3 elements – 1000 kg/hr (2200 lb/hr)

- 4 elements – 1000 kg/hr (2200 lb/hr)

- 5 elements – 725 kg/hr (1600 lb/hr)

- 6 elements – 615 kg/hr (1350 lb/hr)

- Maximum 8 elements

- 2 elements – 4350 kg/hr (9600 lb/hr)

- 3 elements – 3630 kg/hr (8000 lb/hr)

- 4 elements – 3000 kg/hr (6600 lb/hr)

- 5 elements – 2710 kg/hr (5975 lb/hr)

- 6 elements – 2450 kg/hr (5400 lb/hr)

- Maximum 12 elements

WXOmega1 Powder Batch Gravimetric Blender

The EXOmega 1 powder batch gravimetric blender can accommodate up to 8 separate ingredients. Features include, dust-tight construction, integrated matching screw and bridge breaking design. The stainless steel conical weight-hopper design has a integrated butterfly valve along with special load cell technology. PCC’s 3D powder agitator combined with our “upturned Omega” mixing chamber creates the perfect homogenization of powdered blends. Available for many applications to create a mixture of powders and granulates. Throughputs up to 250 kg.hr (550 lb/hr).

Options include: Gravimetric Extrusion Control; Stand with integrated Pickup Box; Adapterpiece for direct mounting onto extruder throat; Touch screen controls with 175 or 250 mm (7 or 10 inch) display; Profibus, Profinet, Modbus OPC IPC UA-Protocol communications protocols.

VNC Viewer Remote Blender Control Panel

The VNC Viewer provides a central control point for an unlimited number of touch screen supplied PCC blenders. Features include:

• 1.2 GHZ Dual-Core Processor.

• Remote viewing for one or multiple controllers at a time.

• 307 mm (12.1 inch) colour TFT touch screen with 1280 x 800 widescreen resolution.

• 512 MB RAM memory.

• DIN rail power supply.

• Preloaded with embedded Linux.

• Preloaded with VNC software for connection to blender.

• Ethernet port for connection to blender.

• Two USB ports for external keyboard and memory card.

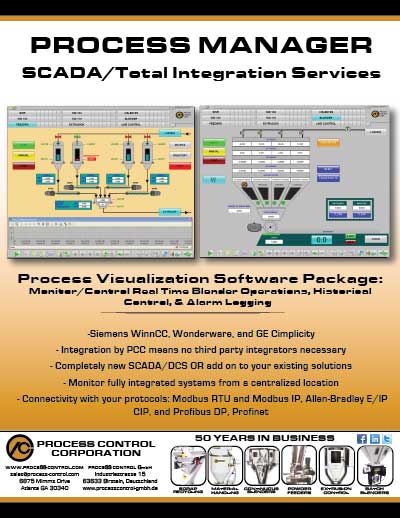

PCC Process Manager

SCADA Total Integration Services includes a process visualization software package. The key advantages are:

- Automatic data acquisition and storage.

- Centralized control or monitoring multiple blenders from one location.

- Ability to distribute data to PC desktop, signage display, handheld tablet for corporate MES/ERP system.

Features include::

- Default configuration is for monitoring and controlling (1) PCC Continuous Blender, (1) PCC Batch Blender, or (1) PCC Gravitrol weigh hopper (with B&R Touchscreen, or Mini-Op equipped with Ethernet capability).

- Virtually limitless expansion of the SCADA system to additional PCC and non-PCC equipment, configured by PCC technicians.

- Includes one runtime version of Siemens WinCC software with SQL server, one license (for one computer only).

- Functions include real time blender operations (both monitor and control), material usage, historical trending, and alarm logging/notifications, all from one centralized location.

- Inventory trends and summary reporting can be exported to any spreadsheet program, such as Excel.

- Operator and Supervisory levels, with multiple security settings available.

- Requires PC with WindowsTM OS 7 or 10 to operate software.

Autobatch and Guardian® Upgrades

Upgrades are available for the Autobatch and original Guardian® Blenders. Standard features include:

- Off-the shelf solution with PLC Controls

- Direct drop in panels and cabling

- Intuitive 145 mm (5.7 inch) colour touch screen interface

- Ability to save configurations to XML

- Remote control by PC via VNC compatible Ethernet connection, with embedded OPC Server

- Guardian® touch screen can be remote mounted

- Saves and restore configuration data and recipes to USB thumb drive

- Alarm notification via email or SMS texts messaging

- Automatic dispense learning when a new recipe is entered

- Ability to download settings and log files over a network via FTP connection

- Advanced control loop for increased accuracy and output

- Ability to show in real time the actual blender and maximum throughput rates based on the current recipe setting

- Ability to show in real time each hopper target and actual dispense weight achieved

- Ability to perform a test dispense for metering accuracy verification